Mechanical Seals in Sealban

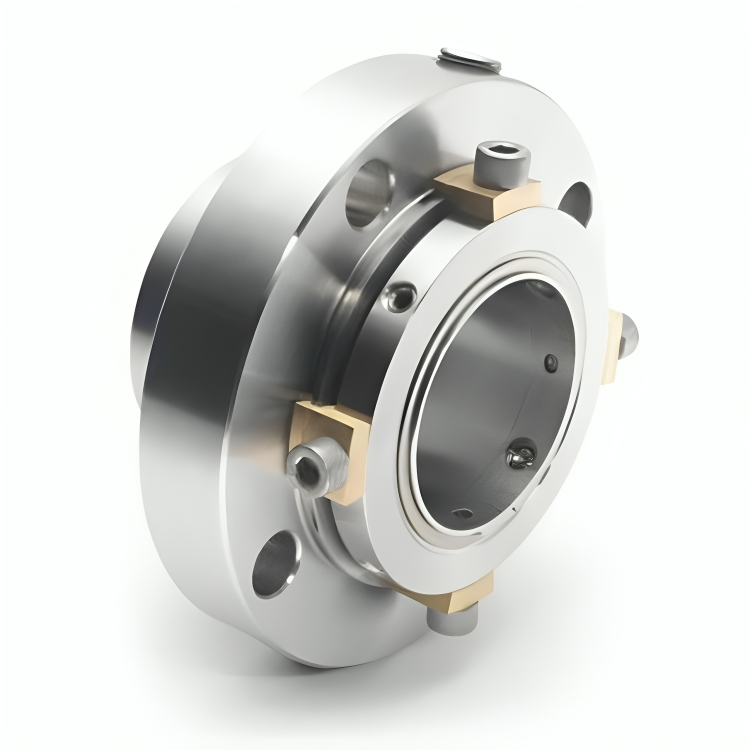

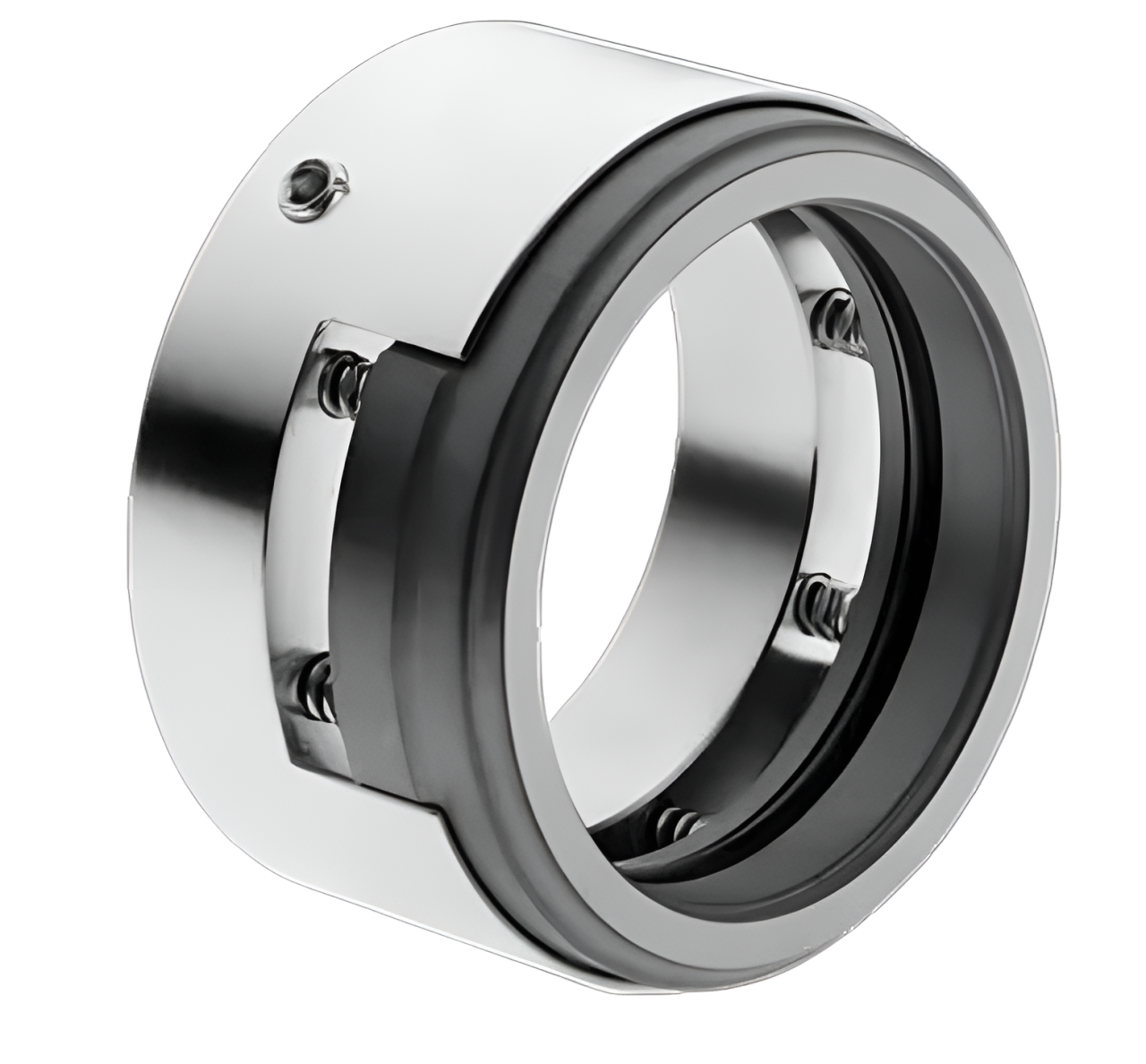

Mechanical Seal:

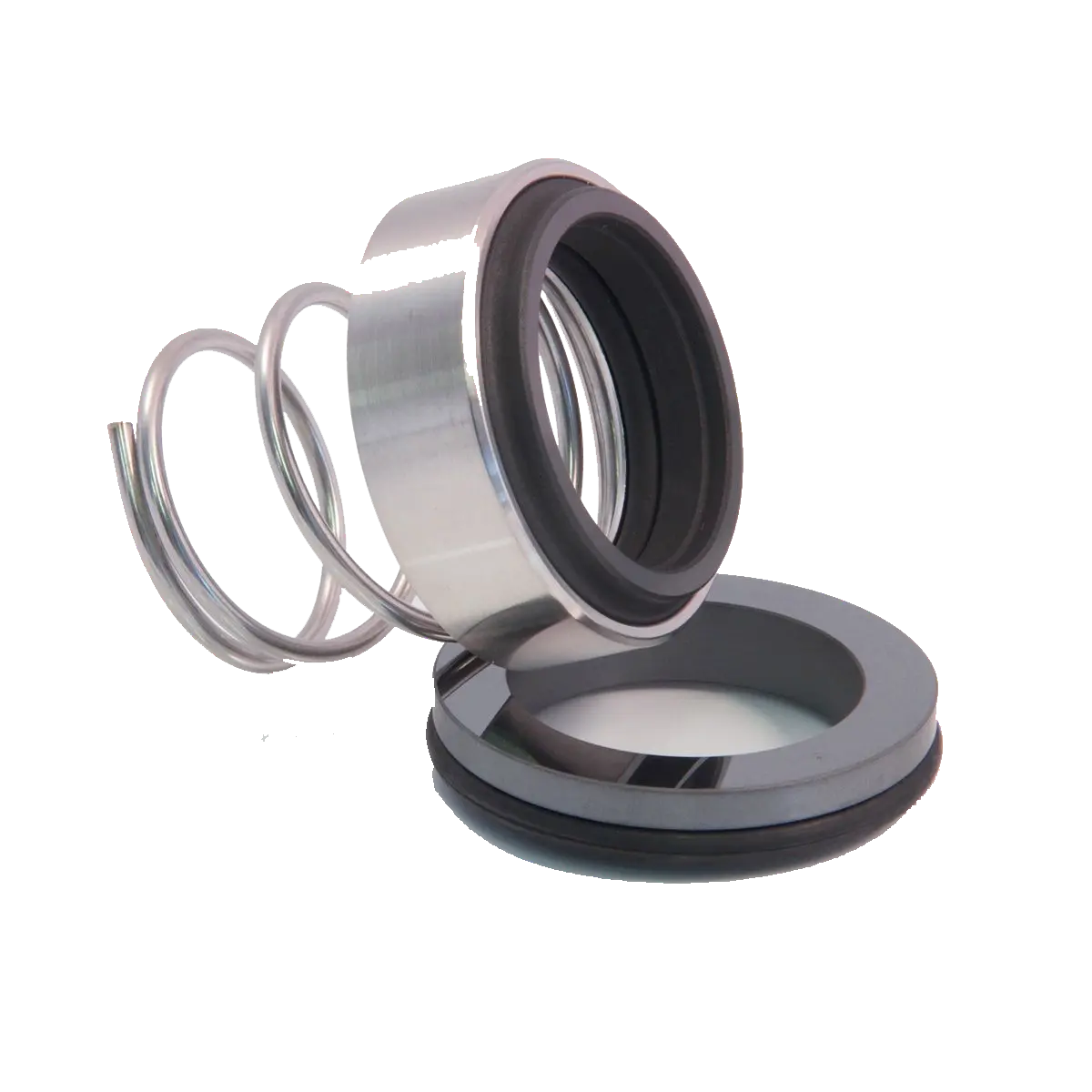

seals are used between engine parts, pumps, and shafts that rotate rather than those that are static. This type of seal is generally a molded or machined product. Seals tend to be flat and round, while gaskets are often cut into different shapes so that they fit the components. Most seals are made of an outer ring that is metal and nests over an inner surface that is often made of rubber. The inner circle is tilted just a bit, which creates a lip for the seal. The lip is designed as a second barrier against any drops that manage to get past the first edge of the seal. It is essential that seals be installed correctly because, if it’s installed backward, you could end up with a leaky mess on your hands.

When a seal breaks down, the entire bearing must be replaced rather than just the seal.

Application:

Common uses for seals include keeping leaks from occurring at the end of the shaft where it comes out of the cover and sealing hydraulic lines. This type of seal is generally a molded or machined product. Seals are often used in bearings, which is basically just a ball bearing surrounded by a rubber seal, which keeps it from leaking and sometimes reduces the amount of noise that occurs during operation.

Mechanical seal Installation:

When installing the seal, it’s usually fitted into the hole by a press. Lubrication is usually necessary to keep the crankshaft from damaging the seal as it goes through it. Sealban Mechanical Seal Installation Guide